Mason Industries - Mason-Mercer

Mason Industries is konwn throughout our industry as one of the pioneers of the Vibration Isolation market. Through relentless product testing and development we are able to provide a reliable and time tested product that is backed by the Mason Industries brand.

Our Engineering department will work tirelessly to provide signed and sealed calculations along with layout drawings and specifications for any of your projects.

We offer our thanks to every contractor and manufacturer who forms our customer base. We believe they favor us because of the practicality of our designs and lower installed cost when product works the first time. We stand behind what we sell as no other competitor. We thank our whole representative organization for their hard work, professionalism, integrity and loyalty. We look forward to serving you. Diversified Fluid Controls is proud to be the exclusive representative for Mason Industries here in South Florida.

Safeflex

Models: SFU, SFDCR, SFDEJ, SFEJ, SFDEH-HE

Safeflex expansion joints are molded and vulcanized in hydraulic presses. This high pressure process produces a smooth finished product with outstanding adhesion between the cover, reinforcement and tube. Most of our competitors still use Natural Rubber impregnated Nylon tire cord between sulfur cured, EPDM covers and tubes. This construction becomes brittle with age at higher temperatures, so we changed from Nylon to Kevlar®, as Kevlar® has a higher modulus that minimizes swell and elongation, and outstanding temperature tolerance up to 250°F (121°C).

Vibraflex

Models: 150, 250, HT250, HT500

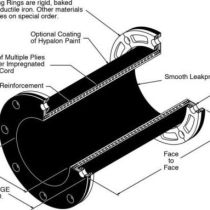

The Vibraflex 150 reinforced rubber pipe is hand built by our skilled craftsmen. To minimize pipe elongation, the carcass is constructed of multiple plies of high tensile polyester tire cord or Kevlar for high temperatures. Helical spring steel wire is imbedded in the carcass to prevent kinking or crushing as well as for radial pressure reinforcement. A variety of cover and tube elastomers are available, offering superior chemical, aging and temperature resistance from -30° to +250°F operating temperatures. Please refer to the choices on the table to the right.

Mercer Expansion Joints

Models: 300, 450, 500, 600, 1000

The Mercer Rubber Company was started in 1865 as a small factory on Mercer Street in Hamilton Square, New Jersey. The company specialized in molded rubber mechanical products, rubber sheeting and conveyor belting, and began building rubber expansion joints in the early 1930’s. Mercer was completely owned by one family from its inception through 1982, when it became a sister to Mason Industries, one of the world’s largest producers of molded rubber expansion joints. Since that time, it has been managed by professional engineers, and we believe our engineering staff is proportionately larger than any other similar company in the United States.

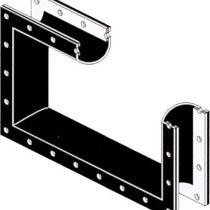

Duct Type Expansion Joints

Models: MA-1, MB-2, MC-3, MD-4, MD-4T

Flexible Connectors are used in DUCT SYSTEMS to reduce Vibration Transmission and Shock, and Accommodate Thermal Movements at minimum stress to the ductwork. In Seismic zones they accommodate differential motion across building expansion joints as well.

Teflon Expansion Joints

Models: 700, HT700, 802, 803, 805

Mercer Invincible Series 700 Teflon® lined expansion joints combine the advantages of Teflon®: Anti-stick properties, Superior Strength, Excellent chemical resistance, Non-aging with the advantages of Mercer’s elastomeric expansion joints,Isolate mechanical vibration,Allow four way movements, Long life expectancy, Absorb pressure surges, Eliminate electrolysis, Small space requirements, Allow four way movements (Axial, lateral, torsional, angular), eliminating problems of pipes buckling or pulling apart.

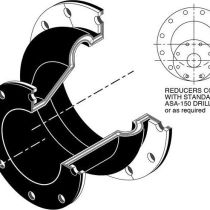

Concentric & Eccentric Reducers

Models: FER501, FCR501

Expansion joints installed in piping systems must be anchored on both sides of the joints to avoid the use of control rods. If control rods are installed as a safety measure, the locking nuts must be backed off with a clearance equal to the specified axial movement. The expansion joint will exert thrust on the anchors.