HydroFlo Pumps

Hydroflo Pumps USA , Inc. was founded in 1998 and incorporated in Tennessee in 2001. Our vision to manufacture the best vertical and submersible turbine pumps in the industry was realized by advancing the standard design to include investment cast stainless steel impellers. The company manufactures the only pump constructed with all- lost wax, investment cast technology. The company’s success has been built on manufacturing, assembling, and delivering the most dependable, purpose engineered pumps in the marketplace. Our engineering staff has combined experience of over 100 years. Today the company continues to grow in the toughest of economic conditions to meet the industry’s demand for the best pump products. Our market segments include agricultural, commercial, industrial, municipal as well as, specialized markets such as mine dewatering, and nuclear plant cooling towers.

Turbines & Pumps

Axial Flow & Mixed Flow Pumps

Flows: Up to 28,000gpm

Total Dynamic Head: 0-185 feet

Speed Ranges: 514 – 1800rpm

AF FEATURES & BENEFITS

- Available in Oil Lube and Product Lube

- Above Ground and Below Grade Discharge Configurations

- Standard all Stainless Steel Bolting

- Hydroflo offers 316SS Impellers for corrosive applications

Fabricated Can Pumps

Flows: up to 15,000gpm

Total Dynamic Head: 0-1,800 feet

Speed Ranges: 900 – 3600rpm

FCP FEATURES & BENEFITS

- Standard Stainless Steel Investment Cast Impellers

- Fabricated Discharge Heads to Match Existing Centerlines

- Standard all Stainless Steel Bolting & Collets

- Fabricated Cans Come Standard with Straightening Vanes

Floating Seal Flush & Water Transfer Pumps

Flows: up to 15,000gpm

Total Dynamic Head: 0 – 1,800 feet

Speed Ranges: 900 – 3600rpm

FSF & WT FEATURES & BENEFITS

- Low Volume High Head & High Volume Low Head Designs Available

- 5HP to 15HP Models & Floats In Stock, Large Units Available

- Single Phase and Three Phase Options

- Clean Water Intake Design with Internal Flow Sleeve for Cooling & Long Life

- Multiple Discharge Options, Including Below Float if needed

Seal Flush Water, Wash Down Stations, Water Transfer, Irrigation Supply Water, and Cooling Water Supply

Horizontal Turbine

Flows: up to 15,000gpm

Total Dyamic Head: 0 – 1.800 feet

Speed Ranges: 900 – 3600rpm

HT FEATURES & BENEFITS

- Standard Stainless Steel Investment Cast Impellers

- Low profile for tight ceiling heights

- Engineered rugged Steel Beam baseplates for harsh handling

- All modular design for ease of inspection/repair/replacement

- Eight optional suction flange orientations for maximum piping flexibility

Highly engineered heavy duty thrust load assembly for maximum life:

- Built-in water cooling jacket for uniform bearing cooling

- Ring oil lubricated bearings for extended life

- Heavy-duty fabricated Steel construction

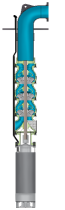

Submersible Turbine Pumps

Flows: up to 15,000gpm

Total Dynamic Head: 0 – 1,800 feet

Speed Ranges: 900 – 3600rpm

SUB FEATURES & BENEFITS

- Standard Stainless Steel Investment Cast Impellers

- 5”- 7” All Ductile Iron Bowl Castings Standard

- Standard all Stainless Steel Bolting & Collets

Vertical Turbine

Flows: up to 15,000gpm

Total Dynamic Head: 0 – 1,800 feet

Speed Ranges: 900 – 3,600rpm

VT FEATURES & BENEFITS

- Standard Stainless Steel Investment Cast Impellers

- Standard Ductile Iron Discharge Heads

- Standard all Stainless Steel Bolting & Collets

- Hydroflo offers all 304SS, 316SS and duplex construction for corrosive applications

- Also offered are ductile iron, long lateral, double bolted pumps for deep set installations.

CP Pumps

Flows: 10 GPM - 260 GPM

Total Dynamic Head: 0 - 325 feet

Speed Ranges: 3600 RPM

CP FEATURES & BENEFITS

- Dynamically balanced stainless steel impeller

- Close coupled design

- DI volutes with threaded connections

- Back Pull-out design

- "Shower-Curtain" Shield Motor Moisture Protection

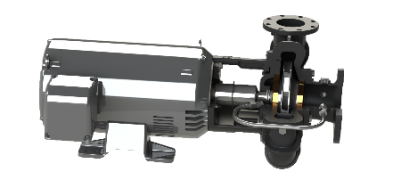

End Suction Pump

Flows: 300 GPM - 35,000 GPM

Total Dynamic Head: 0 - 165 feet

Speed Ranges: 1760 RPM

ESCC FEATURES & BENEFITS

- Strong Ductile Iron Cast Components

- Investment Cast 304 Stainless Steel Impeller

- Standard Off-the-Shelf NEMA motors

- Replaceable Bronze Wear Rings

- Type 1 Mechanical Seal

- Stainless Steel Seal Flush Line

- Dimensionally Interchangeable

- Back Pullout Design

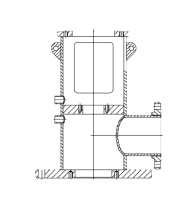

Discharge Heads

Diuctile Iron Discharge Heads

Sizes: 4", 6", 8", 10", & 12"

DI DISCHARGE HEAD FEATURES & BENEFITS

- DI is a superior casting material over Cast Iron

- Provides a better corrosive resistance than cast iron, as well as it handles higher pressures and more hang weight

- Hydroflo provides 4”, 6”, 8” & 10” DI head with identical centerlines. This allows different size pumps to connect into the same height header pipe

- Hydroflo has 4” & 6” DI discharge heads with a 300# ANSI discharge flange

F-Type Fabricated Discharge Head

Sizes: 3" - 24"

F-TYPE DISCHARGE HEAD FEATURES & BENEFITS

- Can match existing center lines

- Designed and Engineered for your specific application

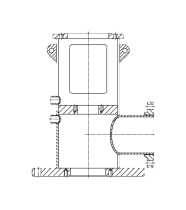

L-Type Fabricated Discharge Head

Sizes: 3” – 24”

F-TYPE DISCHARGE HEAD FEATURES & BENEFITS

- Can match existing center lines

- Designed and Engineered for your specific application

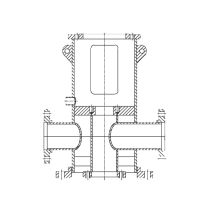

T-Type Fabricated Discharge Head

Sizes: 3 – 20”

F-TYPE DISCHARGE HEAD FEATURES & BENEFITS

- Can match existing center lines

- Designed and Engineered for your specific application

Specialty Products & Accessories

Deep Set Long Lateral Bowls & Impellers

Size Range: 9” & 11”

F-TYPE DISCHARGE HEAD FEATURES & BENEFITS

- Can match existing center lines

- Designed and Engineered for your specific application

Floating Docks & Walkways

Sizes: 12’ x 12’ & 16’ x 16’

F-TYPE DISCHARGE HEAD FEATURES & BENEFITS

- Can match existing center lines

- Designed and Engineered for your specific application

Spiders

Size Range: 4” – 16”

SPIDERS FEATURES & BENEFITS

- Standard Stainless Steel Spiders 4" - 12"

- Standard Ductile Iron Spiders 14" & 16"

- Rubber, FEP, and Graphite Inserts Available

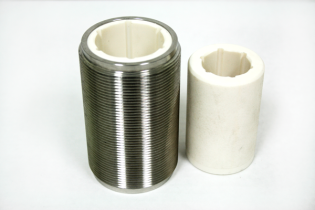

Specialty Bearings

Hydroflo FEP Bearings and Carbon Fiber Graphite

FEP FEATURES & BENEFITS

- Zero Lead

- Run Dry Capability

- Low coefficient of friction

- Better wear characteristics

- Outstanding mechanical properties

CARBON GRAPHITE FEATURES & BENEFITS

- Abrasive Resistance

- Run Dry Capability

- 450 Degree Fahrenheit Exposure

- Material has NSF Approval for Potable Water

- Low Coefficient of Friction

- Extensive List of Chemical Resistance

Mechanical Seals

Size Range: 1” – 2.188”

MECHANICAL SEAL FEATURES & BENEFITS

- Tungsten Carbide and Viton Standard

- Jumbo springs reduce fatigue allowing for greater axial travel, reduces clogging issues, and prohibits chloride stress corrosion

- Micro Polished dynamic o-ring surfaces reduce solids build-up and drag

- Floating stator design assures proper face alignment, improves film/lubrication performance

Our vertical turbine compatible seals offer unmatched value on a cartridge platform. Jumbo springs, floating stator design and our smart drive system comprise the industry’s leader.

Strainers

Cone Strainers, Bolt on Basket Strainers, Screens

STRAINERS FEATURES & BENEFITS

- Standard 304SS Bolt on Basket Strainers

- Standard 6", 8", & 10" 316SS Bolt On Basket Strainers

- Standard Weld On and Threaded Cone Strainers

- Standard Stainless Steel Motor Bracket Screens