Mason Industries - Architectural

Mason Industries is konwn throughout our industry as one of the pioneers of the Vibration Isolation market. Through relentless product testing and development we are able to provide a reliable and time tested product that is backed by the Mason Industries brand.

Our Engineering department will work tirelessly to provide signed and sealed calculations along with layout drawings and specifications for any of your projects.

We offer our thanks to every contractor and manufacturer who forms our customer base. We believe they favor us because of the practicality of our designs and lower installed cost when product works the first time. We stand behind what we sell as no other competitor. We thank our whole representative organization for their hard work, professionalism, integrity and loyalty. We look forward to serving you. Diversified Fluid Controls is proud to be the exclusive representative for Mason Industries here in South Florida.

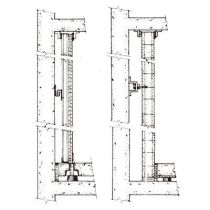

Isolated Walls

Models: DNSB, WIC, NPS, AB-716, SWW

To complete an envelope, secondary walls must be introduced with the same consideration given to mass and air gap as covered in the floor discussion. The problem is simpler, because the walls normally support only their own weight and they need not have the structural strength of the floor. Poured concrete or concrete block walls should approach the floor density. It is most important that block joints are properly filled with mortar and painting the walls so the construction is more nearly airtight helps. The best approach is resting these walls on the perimeter of the floating floor so the floor isolation system serves the walls as well. If this is not possible, the second choice is supporting the isolated wall on the structural slab with continuous LDS pads, and providing a caulked fiberglass seal between the floating floor and the wall as described for the perimeter in the previous specifications.

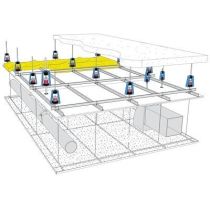

Architectural Ceiling Hangers

Models: 30NCC, 30CC, W30NCC, W30CC, 30CSCH, CRCH, WHR, WHD, W30N, W30, 30SM, WHDSM, 30SMCC, HDSMCC, HDCC, WHDCC

Our recommendations are always based on our best spring products because the additional cost is low as compared to the risk of poor performance. Hanger cost is a small percentage of an acoustical ceiling and it is most important that these sensitive systems are installed with the very best chance of success. We set the spring in a Low Dynamic Stiffness rubber cup molded with a bushing through the lower hole in the steel hanger box. These springs are so large in diameter, compared to the deflected height that the hanger rod can swing 15° in any direction before contacting the rubber bushing. It is very important that this lower rod has that swing capability, because a contractor putting up hangers on 4 ft. (1.2 m) centers finds it almost impossible to keep all of them perfectly plumb. If the hanger rods contact the steel box supplied by many of our competitors, it short-circuits and becomes ineffective.

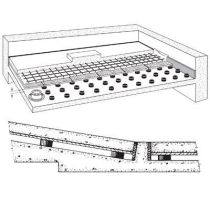

Form Work & Wooden Floating Floors

Models: EAFM, MFS, ND, WFD, SFFS

The alternate, almost obsolete, method is one whereby a continuous layer of the isolation media is used as a pouring surface. More commonly, individual isolators, the thickness of the air gap are placed in position in the field and covered with plywood or factory attached to plywood before delivery. The upper surface is covered with a plastic layer and then the reinforcing is placed on top of the plywood forms and the concrete poured at finished elevation.

Jack-up Floating Floor

Models: FSN, FS, RISFD, RISI, SFFS, CFD

We believe that the most fool-proof and safest way to establish the air gap is the jack-up or lift-slab method. Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings, and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 1” and 4”.