Skidmore

Skidmore has been building the highest-quality condensate return pumps, boiler feed systems, vacuum systems, and accessories since 1921. From custom designs to compact solutions—our skilled representatives are armed with the knowledge and expertise to assist you in the selection, design, installation and service of your pump system. They are backed by a highly skilled team of application specialists who will provide solutions to custom engineering questions or special building capabilities and are committed to developing the most energy efficient pump to fulfill your needs. Every pump that leaves our factory has been carefully crafted and tested against the strictest standards, ensuring you receive the highest-quality product possible. Diversified Fluid Controls is the exclusive Skidmore distributor for the State of Florida.

Boiler Feed Pumps

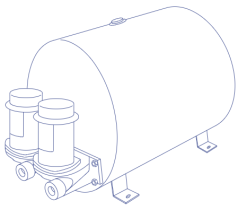

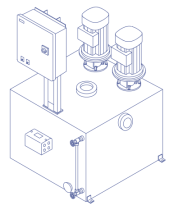

10MX Series Boiler Feed

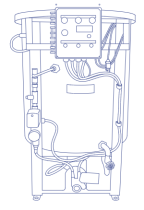

Skidmore 10MX Series Condensate Return and Boiler Feed units are designed to provide maximum efficiency, reliability, and easy maintenance in a compact, space-saving configuration. They are packaged units, completely assembled, wired, and factory tested before shipment to ensure the product is ready for service when it is received. 10MX Series Boiler Feed units are used to pump condensate and makeup water directly into the boiler. Pumping action is determined by a boiler-mounted control that senses boiler water level requirements. Each boiler feed unit is equipped with a heavy-duty makeup valve mounted on the end of the receiver. This valve is activated by the position of its seamless float within the receiver and can be easily removed as a complete unit. Standard simplex or duplex units are available with steel horizontal or vertical receivers in 49-, 71-, 117-, or 209-gallon capacities and include a glass water level gauge with sight glass. When ordering, specify the model number and voltage requirement.

Proctor Series Boiler Feed

Easy to use and maintain, the Protector is known as our most reliable in-stock unit. Available in simplex or duplex units, as well as condensate return or boiler feed units, all Protector series units are capable of handling hot or cold water. Many units have low profiles for low-headroom applications. Protector Boiler Feed units are used to pump condensate and makeup water directly into the boiler(s). Protector Boiler Feed receivers are available in cast iron or carbon steel. Steel offers a broad range of receiver size options, making it perfect for space-saving configurations. Each Skidmore Protector is equipped with a heavy-duty and easily removable float-operated makeup valve. Pumping action is determined by a boiler-mounted level controller that senses boiler water level requirements.

V Series Boiler Feed

Custom-built to meet your requirements, the Skidmore V Series is our most adaptable product line. V Series units are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 100,000 sq. ft. equivalent direct radiation capacities. Many V Series units are ideal for applications with 2′ Net Positive Suction Head Requirements. V Series Boiler Feed units are designed to pump condensate and makeup water directly into the boiler(s) using pressures and flows specifically tailored to boiler specifications. Pumping action is determined by a boiler-mounted level controller that senses water level requirements. We also offer standard float-operated makeup valves or special electric solenoid valves on receivers designed to replenish water inside the boiler feed unit when water levels get too low.

Condensate Return Pumps

10MX Series Condensate Return

Skidmore 10MX Series Condensate Return and Boiler Feed units are designed to provide maximum efficiency, reliability, and easy maintenance in a compact, space-saving configuration. They are packaged units, completely assembled, wired, and factory tested before shipment to ensure the product is ready for service when it is received. 10MX Series Condensate Return units are used in low-pressure heating systems to collect and return condensate to the boiler feed unit. This pump is controlled by the water level in the receiver. When the receiver water level reaches a set point, the high-level float switch starts the return pump(s), pumping the water from the receiver to the boiler feed system. Unlike our 10MX boiler feed units, which are controlled by a boiler-mounted control and equipped with a makeup valve mechanism, 10MX condensate pumps often do not directly supply boiler makeup water.

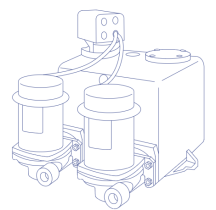

Protector Series Condensate Return

Easy to use and maintain, the Protector is known as our most reliable in-stock unit. Available in simplex or duplex units, as well as condensate return or boiler feed units, all Protector series units are capable of handling hot or cold water. Many units have low profiles for low-headroom applications. Protector Condensate Return units are designed to collect and quickly return condensate to the boiler feed unit in low-pressure steam heat systems. Pumping action is controlled by the water level inside the receiver and a float device is used to turn the pump(s) on and off. Protector Condensate Return receivers are available in cast iron or carbon steel. Please note that steel receivers come in a broad range of size options, making them perfect for space-saving configurations.

V Series Condensate Return

Custom-built to meet your requirements, the Skidmore V Series is our most adaptable product line. V Series units are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 100,000 sq. ft. equivalent direct radiation capacities. Many V Series units are ideal for applications with 2′ Net Positive Suction Head Requirements. V Series Condensate Return units are designed to collect and quickly return condensate to the boiler feed unit using various pressures and flows. Pumping action is controlled by the water level inside the receiver, and an integral float device is used to turn the pump(s) on and off.

High-Pressure Pumps

SCR Series Condensate Return

Skidmore SCR Series products are specifically designed for high-pressure applications and are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 125,000 sq. ft. equivalent direct radiation to 30 to 1,000 boiler horsepower. SCR Series Condensate Return units collect and quickly return condensate to the boiler feed unit using various designed pressures and flows. Steel offers a broad range of receiver size options, making it perfect for space-saving configurations. Pumping action is controlled by the water level inside the receiver and an integral float device is used to turn the pump(s) on and off.

SCRM Series Boiler Feed

Skidmore SCR Series products are specifically designed for high-pressure applications and are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 125,000 sq. ft. equivalent direct radiation to 30 to 1,000 boiler horsepower. SCRM Series Boiler Feed units pump condensate and makeup water directly into the boiler(s) using various pressures and flows specifically tailored to boiler specifications. Pumping action is determined by a boiler-mounted level controller that senses boiler water level requirements. Skidmore offers standard float-operated makeup valves or special electric solenoid valves on receivers designed to replenish water inside the boiler feed unit when water levels get too low.

Stainless Steel Series

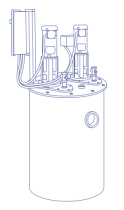

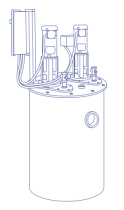

Stainless Steel Top-Mount Condensate Return

Easy to use and maintain, Skidmore Stainless Steel Top-Mount Series Condensate Return units come in three standard sizes, are corrosion-resistant, and are available in simplex or duplex configurations. Our Stainless Steel Top-Mount Series units are designed to collect and quickly return condensate to the boiler feed unit using various pressures and flows. Pumping action is controlled by the water level inside the receiver, and an integral float device is used to turn the pump(s) on and off.

Standard Elevated Pumps

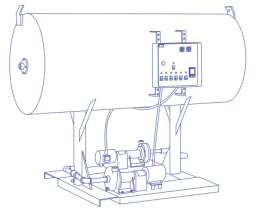

H Series Boiler Feed

An elevated receiver unit using horizontal pumps, H Series pumping systems are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 125,000 sq. ft. equivalent direct radiation or 7.5 to 1,000 boiler horsepower. H Series Boiler Feed units can pump condensate and makeup water directly into the boiler(s) using various pressures and flows. Pumping action is determined by a boiler-mounted level controller that senses boiler water level requirements. We offer standard float-operated makeup valves or special electric solenoid valves that are designed to replenish water inside the boiler feed unit when water levels get too low. Attached horizontal pump(s) sit beneath an elevated receiver on a structural steel base.

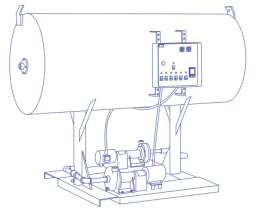

H Series Condensate Return

An elevated receiver unit using horizontal pumps, H Series pumping systems are available in simplex, duplex, triplex, or quadruplex configurations from 1,000 to 125,000 sq. ft. equivalent direct radiation or 7.5 to 1,000 boiler horsepower. H Series Condensate Return units can collect and quickly return condensate to the boiler feed unit using various pressures and flows. Pumping action is controlled by the water level inside the receiver and an integral float device is used to turn the pump(s) on and off. An attached horizontal pump and a 30-inch structural steel base stand are located below each receiver.

Vacuum Pumps

PRVC Series Vacuum Condensate

All PRV Series units utilize positive-displacement bronze-fitted, close-coupled pump assemblies. PRVC Series Vacuum/Condensate units are used in positive-displacement vacuum condensate return applications. These large-air-capacity vacuum heating pumps provide quick and positive removal of air and condensate from all distant areas, ensuring quicker warm-up, better heat, and lower fuel costs.

JVC Series Condensate Return

JV Series units produce a powerful vacuum that allows boilers to operate at a lower pressure, minimizing heat loss and reducing heating costs. Units are available in simplex, semi-duplex, and duplex models. JVC Series Vacuum/Condensate Return units collect and quickly return condensate to the boiler feed unit using various designed pressures and flows. Pumping action is controlled by the water level inside the receiver and uses either a standard float switch or a mechanical alternator to turn the pump(s) on and off. The water passes through a Venturi, creating a powerful vacuum that aids in air removal from the system and allows steam to travel long runs.

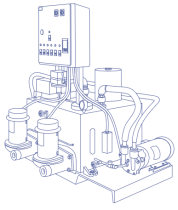

PDVC Series Condensate Return

PD Series units produce a powerful vacuum that allows boilers to operate at a lower pressure, minimizing heat loss and reducing heating costs. Units are available in simplex, semi-duplex, and duplex models. PDVC Series Positive Displacement Vacuum/Condensate Return units are designed to collect and quickly return condensate to the boiler feed unit using various designed pressures and flows. Pumping action is controlled by the water level inside the receiver and a standard float switch or a mechanical alternator is used to turn the pump(s) on and off. Liquid-Ring Vacuum pumps come with durable impellers designed for smooth and efficient water passage and produce a liquid seal in the water tank when running.

PRVBF Series Boiler Feed

All PRV Series units utilize positive-displacement bronze-fitted, close-coupled pump assemblies. PRVBF Series Vacuum/Boiler Feed units are for boiler feed and makeup water installations. These large-air-capacity vacuum heating pumps provide quick and positive removal of air and condensate from all distant areas, ensuring quicker warm-up, better heat, and lower fuel costs.

JVBF Series Boiler Feed

JV Series units produce a powerful vacuum that allows boilers to operate at a lower pressure, minimizing heat loss and reducing heating costs. Units are available in simplex, semi-duplex, and duplex models. JVBF Series Vacuum/Boiler Feed units pump condensate and makeup water directly into the boiler(s) using various pressures and flows specifically tailored to boiler specifications. Pumping action is determined by a boiler-mounted level controller and offers standard float-operated makeup valves on receivers designed to replenish water inside the boiler feeds unit when water levels get too low. The water passes through a Venturi, creating a powerful vacuum that aids in air removal from the system and allows steam to travel long runs.

PDBF Series Boiler Feed

PD Series units produce a powerful vacuum that allows boilers to operate at a lower pressure, minimizing heat loss and reducing heating costs. Units are available in simplex, semi-duplex, and duplex models. PDBF Series Positive Displacement Vacuum/Boiler Feed units are designed to pump condensate and makeup water directly into the boiler(s) using various pressures and flows specifically tailored to boiler specifications. Pumping action is determined by a boiler-mounted level controller and offers standard float-operated makeup valves or special electric solenoid valves on receivers designed to replenish water inside the boiler feed unit when water levels get too low. Liquid-ring Vacuum pumps come with durable impellers designed for smooth and efficient water passage and produce a liquid seal in the water tank when running.

Sump Pumps

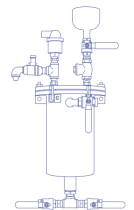

UV Series Boiler Feed

UV Series units are uniquely designed for below-grade applications. Each pump consists of a vertical pump and motor unit and has either a flange-type float switch mechanism to control pumping from the water level in the receiver or a flange-type float-operated makeup valve to control pumping from the water level in the boiler. UV Series Boiler Feed units collect condensate below floor level and then pump condensate and makeup water directly into the boiler(s) using various pressures and flows. Pumping action is determined by a boiler-mounted level controller that senses boiler water level requirements. Skidmore offers standard float-operated makeup valves or special electric solenoid valves on receivers designed to replenish water inside the boiler feed unit when water levels get too low.

UV Series Condensate Return

UV Series units are uniquely designed for below-grade applications. Each pump consists of a vertical pump and motor unit and has either a flange-type float switch mechanism to control pumping from the water level in the receiver or a flange-type float-operated makeup valve to control pumping from the water level in the boiler. UV Series Condensate Return units are designed to collect condensate below floor level and quickly return it to the boiler feed unit using various pressures and flows. Pumping action is controlled by the water level inside the receiver and an integral and adjustable float device is used to turn the pump(s) on and off.

Water Treatment

Glycol Systems

From chilled water to snowmelt, radiant heat, and closed-loop heating—the Skidmore Glycol Feed is designed to bring an automatic supply of water-glycol mix to any heating or cooling closed-loop system. Factory engineered and assembled, Glycol Feed units are available in 6, 16, 55, and 100 gallon capacities. These compact and self-contained units make for an easy install and no-hassle operation. Easy plug ‘n play run capability also allows for immediate usage.

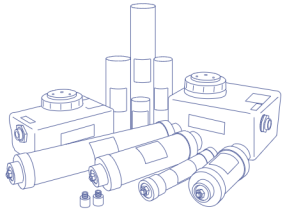

X-Pot

Designed to improve water quality and reduce heating and cooling costs, the X-POT is an all-in-one slipstream filter, magnetic filter, air separator and shot feeder. This unit is available in three sizes. Compact and versatile, the X-POT Compact® was specifically designed for smaller commercial heating and cooling water installations up to 9,130 gallons and 150 psi working pressure. The X-POT6® works well with many system sizes and contains six rare earth magnets encased within a stainless steel magnet grate for easy removal and cleaning. Designed for the large commercial heating and cooling water installations up to 79,886 gallons in volume, the X-POT XP® is the new industry benchmark for slipstream filtration.

Condensate Neutralizers

Easy to install and to service, the Skidmore Condensate Neutralizer is designed to completely neutralize your condensate before the acidic substance can cause serious damage to drainage piping and fittings. The media—found inside a clear tube—is made of a clean screened calcite and magnesium oxide that raise the pH levels and help change the acidic solution into water, CO2, and various salts.

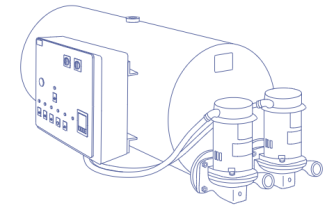

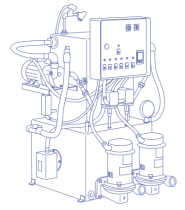

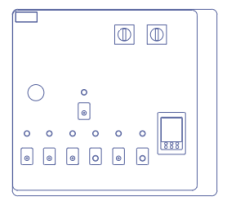

Control Panels

Control Panels

Control panels can be tailored to your specific application requirements. Each panel is designed to prevent accidental contact with the enclosed equipment. All panels are UL508A certified. The 550 Series Control Panel is intended for indoor use. These panels are non-ventilated and come standard as a Type 1 NEMA enclosure, with a reset button in the cover and two starters with overload protection. The 700 Series Control Panel is intended for indoor and outdoor use. These panels are non-ventilated and available in Type 1, 2, 3, 4X, and 12 NEMA enclosures, depending on what best suits the environment. Every control panel comes standard with one starter complete with overload protection per pump, along with a numbered terminal strip and ground lug.