Thermacor Process, Inc.

Diversified Fluid Controls, inc. is the exclusive representative for Thermacor Pre-insulated underground piping. Thermacor is a leading provider of pre-insulated piping systems in the industrial, commercial, institutional, power generation, and military piping markets among others. We manufacture superior systems for steam, condensate, chilled water, heating water, high temperature hot water, cryogenics, jet fuel, solvents, oil, and other domestic and industrial applications including those systems that require heat tracing or freeze protection. We also offer services for stress analysis, heat gain/loss calculations and infrared thermography of your piping system.

Ferro-Therm

THERMACOR’S FERRO-THERM is a factory-fabricated, pre-insulated piping system for below ground or above ground distribution of hot water, chill water, low-pressure steam, condensate, oil and viscous fluids. The system is designed with a steel carrier pipe as required, polyurethane foam insulation (rated to 250°F) and a high density polyethylene (HDPE) jacket.

Carrier Pipe:

• Steel (type and grade specified, as required)

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

• Type 1, Class 1 PVC

Chill-Therm

THERMACOR’S CHILL-THERM is a factory-fabricated, pre-insulated piping system for the below ground distribution of chilled water. The system is designed with a PVC plastic pressure carrier pipe (type to be specified), polyurethane foam insulation, and a high density polyethylene (HDPE) or PVC jacket.

Carrier Pipe:

• Class 160 (SDR 26)

• Class 200 (SDR 21)

• C900/905

• Schedule 40/80 Solvent Weld

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

• Type 1, Clas 1 PVC

Fiber-Therm

THERMACOR’S FIBER-THERM is a factory-fabricated, pre-insulated piping system for the distribution of chilled water, low temperature hot water, steam and condensate up to 250°F. FIBER-THERM is designed with fiberglass reinforced plastic (FRP) pressure pipe, closed cell polyurethane foam insulation, and either a high-density polyethylene (HDPE) or PVC jacket.

Carrier Pipe:

• FRP – Fiberglass Reinforced Plastic per specification

• Polyurethane foam

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

• Type 1, Clas 1 PVC

Spiral Therm

THERMACOR’S SPIRAL-THERM is a metal jacketed, factory-fabricated, pre-insulated piping system for above ground, shallow concrete trench, and tunnel piping applications. SPIRAL-THERM incorporates the insulation, or combination of insulations, of choice within a durable protective metal jacket (aluminum, galvanized steel, or stainless steel). The spiral lock seam, either internal or external, is air and watertight.

Carrier Pipe:

• As Specified

Insulation:

• Polyurethane foam

Spiral Wound Jacket:

• Aluminum, Galvanized Steel, or Stainless Steel

• Internal or External Seam

• Watertight rubber o-ring sealed seam

Copper-Therm

THERMACOR’S COPPER-THERM is a factory-fabricated, pre-insulated piping system for below ground distribution of heating water, domestic hot water, chill water, condensate return, process fluids, and cryogenic services. COPPER-THERM is designed with copper tubing (type to be specified), closed cell polyurethane foam insulation (rated to 250°F), and a high density polyethylene (HDPE) or PVC jacket. O-ring couplings are also available for joining straight lengths of pipe to compensate for thermal expansion.

Carrier Pipe:

• Type “K” Copper

• Type “L” Copper

• Type “M” Copper

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

• Type 1, Class 1 PVC

Ferro-Therm D.I.

THERMACOR’S FERRO-THERM D.I. is a factory-fabricated, pre-insulated piping system for below and above ground distribution of chilled water or domestic hot water. The system is designed with ductile iron pressure pipe, closed cell polyurethane foam insulation, and a high density polyethylene jacket.

Carrier Pipe:

• Ductile Iron (as specified)

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

Polycor Platinum

THERMACOR’S POLYCOR™ PLATINUM™ is a factory-fabricated, pre-insulated piping system for hot water distribution up to 180°F. POLYCOR™ PLATINUM™ is designed with PERT (Polyethylene-Raised Temperature) carrier pipe, closed cell polyurethane foam insulation, and a high density polyethylene jacket.

Carrier Pipe:

• PERT-High Density Polyethylene

Insulation:

• Polyurethane foam

Jacket:

• High Density Polyethylene (HDPE)

CON II

Pre-engineered, pre-fabricated containment piping system designed to provide maximum safety for transporting hazardous fluids above or below ground.

Carrier Pipe:

• d ≥ 2” – A53 ERW Grade B, Std. Wt. Black Steel

• d < 2” – A106 SML, Std. Wt. Black Steel • Seamless & Schedule 80 pipe are available for all sizes • Std. Wt. is the same as Schedule 40 through 10” • XS is the same as Schedule 80 through 8” • Stainless Steel

Containment Pipe

• 10 Gauge, smooth wall black steel conduit

• A53 ERW Grade B, Ste. Wt. Black Steel

Containment Coating

• Novacoat –30 mils

• Fusion Bonded Epoxy – 20 mils

• Primer for Above Ground

Special Features

Pre-Fabricated / Pre-Engineered Systems

Prefab systems are part of a complete piping system designed and manufactured to jobsite dimensions in order to minimize field welds. Prefab systems are delivered to the jobsite as part of a completely pre-engineered system. Thermacor can also offer stress analysis reports, heat loss/gain calculations or design help for this system as well as with others. This system is the highest quality option available. The contractor has only to assemble the numbered pieces as shown on our engineered site drawing, and then field insulate the joints.

Pressure Testable Joint Kits

Utilizes an electric-fusion stainless steel wire embedded in an easy-to-install wrap-around HDPE sleeve. By applying a 12 amp electric current, the wire melts and fuses the surrounding sleeve and jacket together to create a pressure testable watertight seal. The joint is tested at a recommended 5 psi, and becomes mechanically as strong as the HDPE jacket itself when fused properly. The pressure-testable closure ensures watertight integrity of the critical pipe joint connections and can be used on all HDPE jacketed systems.

Ferro-Therm SC & Copper-Therm SC

Ferro-Therm SC and Copper-Therm SC are standard component piping products for above and below ground applications. Fittings and accessory components are delivered to the jobsite in standard sizes and configurations for ease of installing the systems. This product provides better security than field-insulated systems because the pre-insulated components are manufactured under quality controlled factory conditions. The contractor is only required to make field cuts where needed, attach the SC fitting and then field insulate the 12” straight joints.

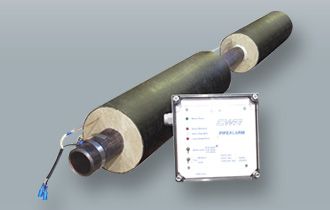

ERM Leak Detection

Electric Resistance Monitoring provides easy to monitor leak detection in foam insulated piping systems. The ERM system is simply a bare copper wire embedded in the insulating foam. Since the foam is not a conductor of electricity, there will be very high resistance between the wire and the metal pipe (reading 100,000+ Ohms). If the foam becomes wet, the water will complete the circuit and the resistance will drop to values approaching zero.